Stud wall insulation refers to the process of adding insulation material to the walls of a stud frame construction. In stud wall construction, vertical wooden or metal framework members called studs are spaced apart and covered with wall cladding, such as plasterboard or drywall. The insulation is installed between these studs to improve the thermal and acoustic performance of the wall.

In this comprehensive guide, we will explore the various types of stud wall insulation available, their benefits, and the installation techniques to ensure optimal results. From thermal insulation for internal stud walls to acoustic insulation for partition walls, we’ll cover everything you need to know to make an informed decision for your insulation project.

We will cover

1. Understanding the Basics and Benefits of Stud Wall Insulation

2. Benefits of Stud Wall Insulation

3. The Best types/Options for Stud Wall Insulation

4. Why Choose ROCKWOOL Solutions for Stud Wall Insulation?

5. How to Choose the Right Stud Wall Insulation For Your Home

6. Selecting the Right Materials for Stud Wall Insulation

7. Step-by-Step Guide: Installing Stud Wall Insulation for Energy Efficiency and Soundproofing

Understanding the Basics of Stud Wall Insulation

Stud wall insulation plays a vital role in improving the sound and fire-resistant properties of buildings. It involves filling the space within stud walls to create a barrier against noise and enhance safety. This section will delve deeper into the concept of stud wall insulation and its importance in construction projects.

Stud wall insulation is an important aspect of building construction that helps improve energy efficiency, comfort, and soundproofing in residential and commercial buildings. Understanding the basics and benefits of stud wall insulation can help you make informed decisions about insulating your walls.

Benefits of Stud Wall Insulation

Thermal Efficiency

Insulating stud walls helps to minimize heat loss or gain through the walls, keeping the indoor temperature more stable and comfortable throughout the year. It reduces the reliance on heating and cooling systems, leading to energy savings and lower utility bills.

Energy Savings

Properly insulated stud walls contribute to overall energy efficiency in buildings by reducing the need for excessive heating or cooling. This not only saves money but also helps to reduce greenhouse gas emissions and the environmental impact of the building. UK government initiates energy savings program and launched ECO4 Grant, under which you can get free boiler replacement and home insulations.

Soundproofing

Insulation in stud walls can help to dampen sound transmission between rooms or from outside noise sources. It improves acoustic comfort by reducing the transfer of airborne sounds, providing a quieter indoor environment.

Condensation Control

Insulation can help to prevent condensation on interior walls by maintaining a consistent temperature on the surface. By reducing moisture buildup, it helps to prevent mold growth and potential damage to the walls.

Fire Resistance

Some insulation materials used in stud wall insulation, such as mineral wool, offer fire-resistant properties. This can help to slow down the spread of fire, providing additional safety benefits.

Improved Building Performance

Properly insulated stud walls contribute to the overall performance of the building envelope, enhancing its durability, structural integrity, and occupant comfort.

Types of Stud Wall Insulation

When it comes to stud wall insulation, there are several options available to suit different insulation needs. The best option for you will depend on factors such as your budget, desired insulation performance, and any specific requirements you may have, such as thermal efficiency or soundproofing. Here are some of the top options for stud wall insulation:

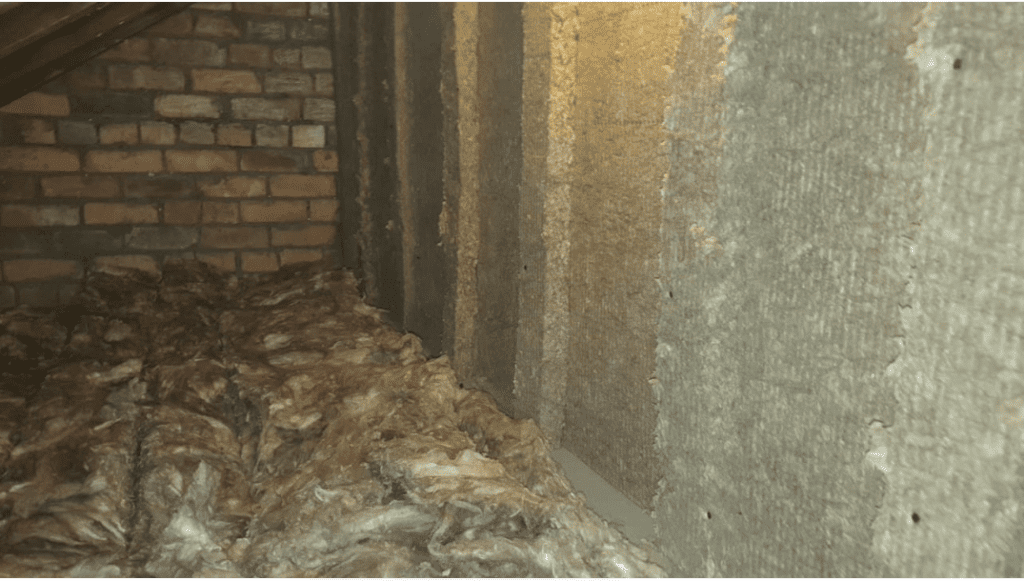

Fiberglass Insulation

Fiberglass insulation is one of the most common and affordable options for stud wall insulation. It consists of fine glass fibers that trap air, providing effective thermal insulation. Fiberglass insulation is available in batts or rolls, making it easy to install between studs. It also offers decent soundproofing properties.

Mineral Wool Insulation

Mineral wool insulation, also known as rock wool or stone wool, is made from natural minerals such as basalt or diabase. It offers excellent thermal insulation and is also fire-resistant. Mineral wool insulation is available in batts or loose-fill form, providing flexibility for installation in stud walls.

Cellulose Insulation

Cellulose insulation is made from recycled paper treated with fire-retardant chemicals. It is an eco-friendly option that provides good thermal insulation and soundproofing. Cellulose insulation is typically blown into the wall cavities using specialized equipment, ensuring a tight and efficient fit.

Spray Foam Insulation

Spray foam insulation is a popular choice for stud walls as it expands and fills gaps, creating an airtight seal. It offers excellent thermal insulation and can also provide soundproofing benefits. Spray foam insulation is applied as a liquid that expands into a foam, adhering to the wall surface and filling cavities.

Rigid Foam Insulation

Rigid foam insulation panels, such as expanded polystyrene (EPS) or extruded polystyrene (XPS), provide high thermal resistance in a relatively thin profile. They can be installed directly against the stud wall, providing continuous insulation and minimizing thermal bridging. Rigid foam insulation also offers good moisture resistance.

Reflective Insulation

Reflective insulation utilizes a reflective surface, often aluminum foil, to reflect radiant heat. It is typically installed as a barrier between the stud wall and the interior finish. Reflective insulation is effective in reducing heat gain in hot climates, but its thermal performance may vary depending on the installation and the presence of an air gap.

Remember, the best option for stud wall insulation will depend on your specific requirements and budget. It is advisable to consult with insulation professionals or contractors who can assess your needs and recommend the most suitable insulation solution for your stud walls.

Why Choose ROCKWOOL Solutions for Stud Wall Insulation?

Choosing ROCKWOOL solutions for stud wall insulation offers several benefits due to the unique properties of ROCKWOOL insulation products.

Here are some reasons why you might consider ROCKWOOL for your stud wall insulation

Excellent Thermal Performance

ROCKWOOL insulation has high thermal resistance, meaning it effectively reduces heat transfer through the walls. By installing ROCKWOOL insulation in stud walls, you can create a thermal barrier that helps maintain a comfortable indoor temperature while reducing energy consumption for heating and cooling.

Fire Resistance

One of the notable advantages of ROCKWOOL insulation is its exceptional fire resistance. It is made from stone wool, a non-combustible material that can withstand high temperatures. In the event of a fire, ROCKWOOL insulation can help slow down the spread of flames and provide valuable time for evacuation.

Sound Absorption

ROCKWOOL insulation has excellent sound absorption properties, making it an ideal choice for reducing noise transmission through stud walls. Whether you want to minimize sound from adjacent rooms or block external noise sources, ROCKWOOL insulation can help create a quieter and more peaceful indoor environment.

Durability and Longevity

ROCKWOOL insulation is known for its durability and long lifespan. It is resistant to moisture, rot, and mold growth, ensuring that your stud walls remain protected and insulated over time. The stable and non-settling nature of ROCKWOOL insulation ensures its effectiveness for years to come.

Sustainable and Environmentally Friendly

ROCKWOOL insulation is made from volcanic rock and contains up to 75% recycled content. It is a sustainable and environmentally friendly choice for insulation. ROCKWOOL products are also low in volatile organic compounds (VOCs), contributing to better indoor air quality.

Easy Installation

ROCKWOOL insulation is designed for easy installation in stud walls. It is available in various sizes and formats, such as batts or boards, allowing for flexible application. The insulation is lightweight, making it easier to handle during installation.

Acoustic and Thermal Performance in One

ROCKWOOL insulation products provide a combination of excellent acoustic and thermal performance. By choosing ROCKWOOL for stud wall insulation, you can achieve both energy efficiency and soundproofing benefits in a single solution.

When considering ROCKWOOL insulation or any other insulation material, it’s important to assess your specific requirements, budget, and local building codes.

How to Choose the Right Stud Wall Insulation For Your Home

Choosing the right stud wall insulation for your home is crucial to maximize energy efficiency, comfort, and overall performance. Here are some factors to consider when selecting stud wall insulation

Insulation Material

There are various insulation materials available for stud walls, including fiberglass, mineral wool, cellulose, and foam insulation. Each material has its own advantages and considerations. Fiberglass insulation is affordable and widely used, while mineral wool offers excellent fire resistance and soundproofing. Cellulose insulation is eco-friendly and has good thermal performance. Foam insulation provides high R-value and can effectively seal air leaks. Consider your specific needs and priorities when evaluating different insulation materials.

R-value

The R-value measures the thermal resistance of insulation—the higher the R-value, the better the insulation’s ability to resist heat flow. The appropriate R-value for stud wall insulation depends on your climate zone and local building codes. Higher R-values are recommended for colder climates, while lower R-values may be suitable for milder regions. Consult local building authorities or insulation professionals to determine the recommended R-value for your area.

Wall Cavity Size

The size of the wall cavities in your home’s stud walls will determine the type of insulation that can be used. Standard stud walls typically have a cavity width of 16 or 24 inches. Ensure that the insulation material you choose fits the cavity size properly to achieve optimal performance.

Moisture Resistance

Consider the moisture conditions in your home when selecting stud wall insulation. If you have a moisture issue or live in a humid climate, choose an insulation material that is resistant to moisture and does not promote mold growth. Some insulation materials, such as closed-cell foam insulation or certain types of mineral wool, offer good moisture resistance.

Fire Safety

Fire resistance is an important consideration for stud wall insulation. Look for insulation materials that have a high fire resistance rating, such as mineral wool or certain types of fiberglass insulation. These materials can help slow down the spread of flames and provide valuable time for evacuation in the event of a fire.

Soundproofing Requirements

If reducing noise transmission is a priority, consider insulation materials with good sound absorption properties. Mineral wool and certain types of fiberglass insulation are known for their soundproofing capabilities and can help create a quieter indoor environment.

Environmental Impact

If sustainability is a concern, choose insulation materials with a high recycled content and low environmental impact. Materials like cellulose insulation or mineral wool made from recycled materials can be more environmentally friendly choices.

Budget

Evaluate the cost of different insulation materials and consider your budget. While some insulation materials may have a higher upfront cost, they can provide long-term energy savings that offset the initial investment.

It’s advisable to consult insulation professionals or contractors who can assess your specific needs, provide recommendations, and ensure proper installation of the chosen stud wall insulation.

Selecting the Right Materials for Stud Wall Insulation

Selecting the right materials for stud wall insulation is crucial to ensure optimal performance and energy efficiency. Here are some considerations to help you make an informed decision

1. Fiberglass Insulation

Fiberglass insulation is a popular choice for stud wall insulation. It is available in batts or rolls and offers good thermal performance. It is generally affordable and easy to install, making it a common option for DIY projects.

2. Mineral Wool Insulation

Mineral wool, also known as rock wool or stone wool, is another effective option. It provides excellent thermal and sound insulation properties. Mineral wool is non-combustible, which enhances fire safety. It is available in batts or loose-fill form and can be installed in stud wall cavities.

3. Cellulose Insulation

Cellulose insulation is made from recycled paper and treated with fire-retardant chemicals. It offers good thermal and sound insulation, and its loose-fill form can be blown into stud wall cavities. Cellulose insulation is environmentally friendly and has decent moisture resistance.

4. Polystyrene Insulation

Polystyrene insulation, available in both expanded (EPS) and extruded (XPS) forms, provides good thermal insulation. It is lightweight, moisture-resistant, and easy to handle. Polystyrene panels can be fitted between studs or used as a continuous insulation layer on the exterior side of the studs.

5. Polyurethane Spray Foam Insulation

Polyurethane spray foam insulation offers excellent thermal insulation and air sealing properties. It expands to fill cavities completely, providing a high R-value and reducing heat loss. Spray foam insulation needs to be installed by professionals and requires proper ventilation during installation.

6. Consider Hybrid Approaches

Some articles mention hybrid approaches, combining different insulation materials for enhanced performance. For example, using rigid foam boards in combination with fiberglass batts can provide both thermal and air barrier benefits.

7. Consider Environmental Impact

If environmental sustainability is a priority, look for insulation materials with high recycled content or those made from renewable resources. Mineral wool and cellulose insulation are often mentioned as eco-friendly options.

8. Assess Performance Factors

Evaluate the insulation materials based on their thermal resistance (R-value), sound insulation properties (STC or NRC ratings), fire resistance, moisture resistance, and any specific requirements you may have for your home.